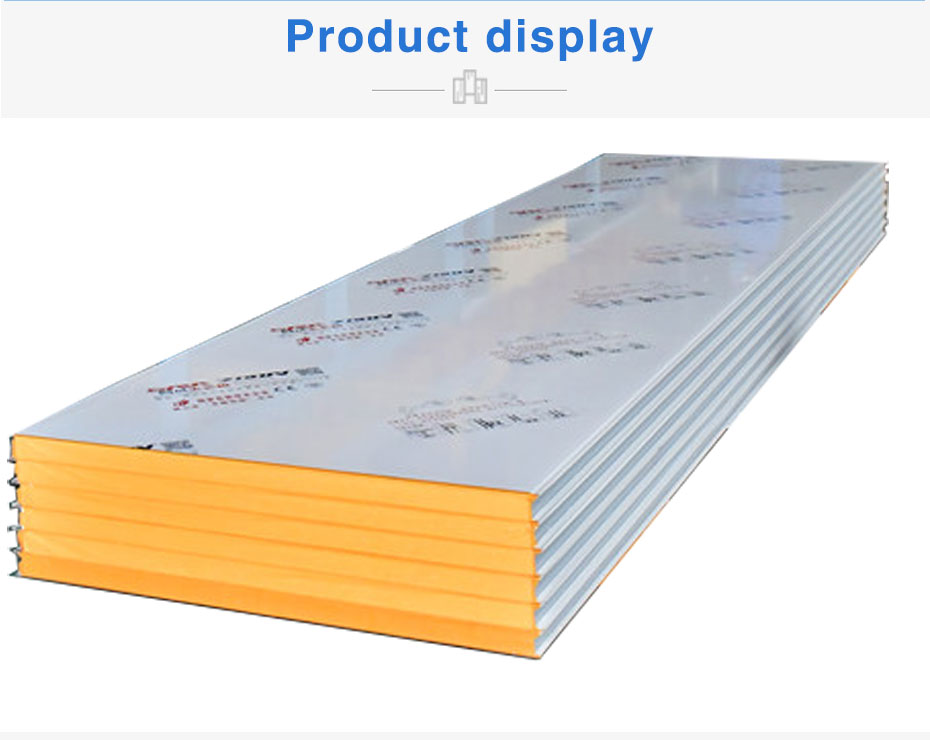

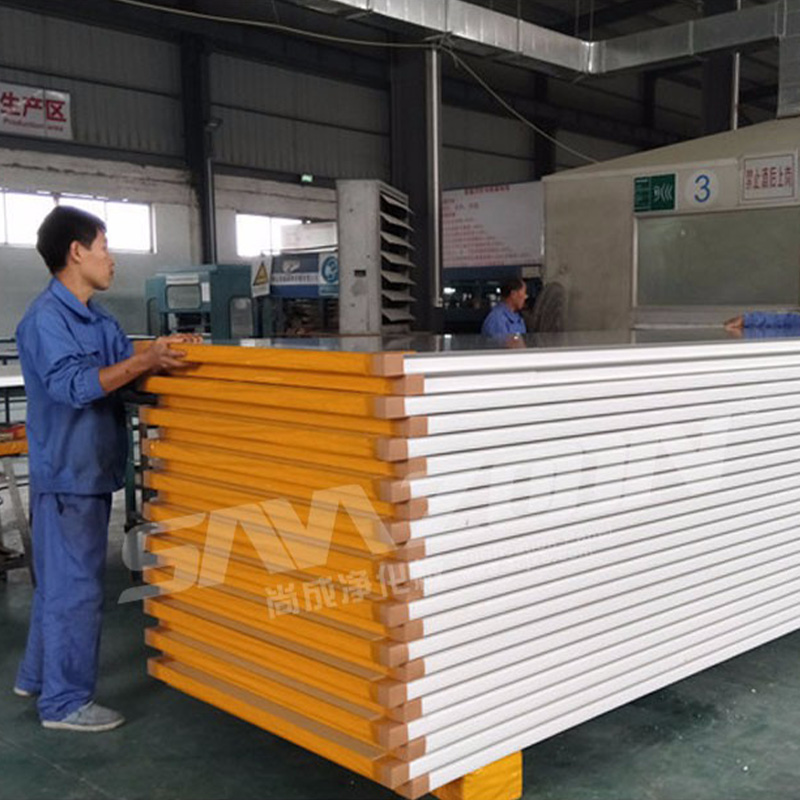

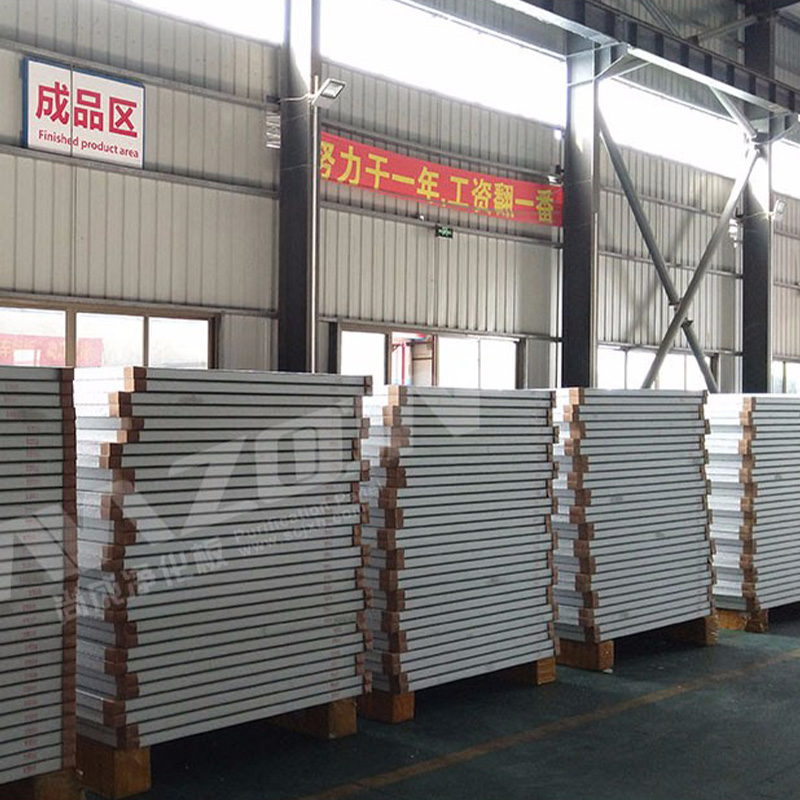

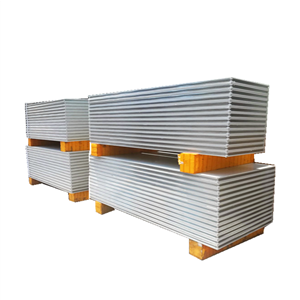

Building Panels Light Weight Easy Install Eps Insulated Sandwich Panels

- samzoon

- foshan

- 7days

- 3000 square meters per day

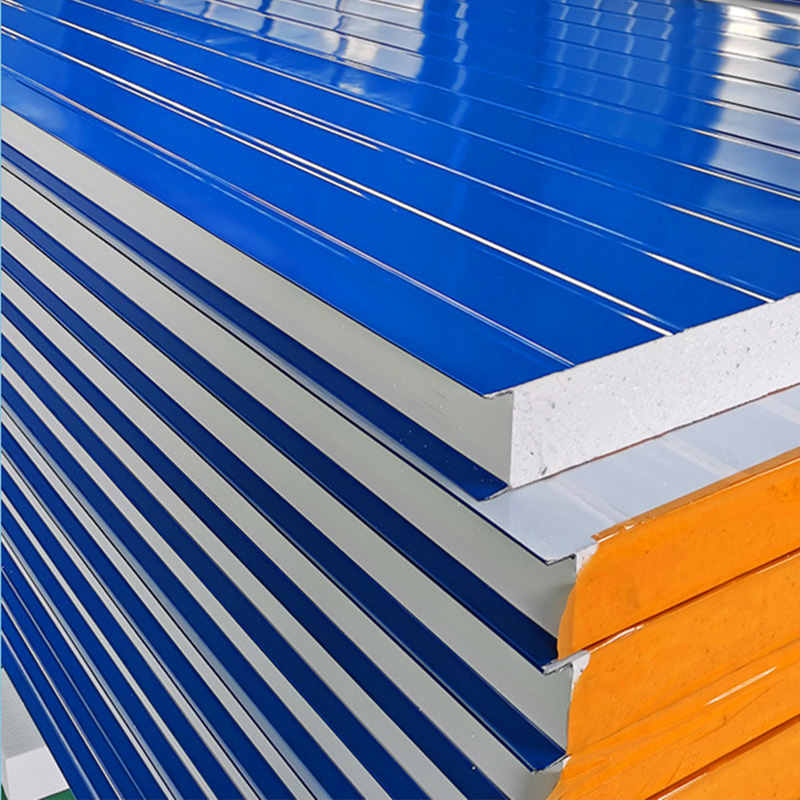

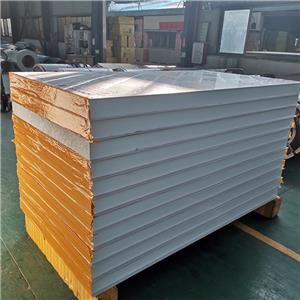

S-type export trade EPS composite board interface has changed the technical difficulties of Guangdong over the past 20 years. It is also the latest sandwich panel manufacturer using S foam interface in the whole industry. The innovation of S export trade EPS/ foam composite board has changed the two sides of the board, flat and beautiful, without gaps. The cliff is as smooth as a knife. There is no gap and no joint. The gap can be controlled within 0.2-0.5mm. S-type export trade EPS

The composite board has the following characteristics:

① Version docking has changed the problem of horizontal docking dislocation in the past.

② After the steel plate is produced, there is no gap and joint, which solves the problem of joint ridge mark on the surface.

③ It solves the problem of poor thermal insulation effect of cold storage room and constant temperature room by flat butt joint in the past.

⑤ The problem of insufficient strength caused by dislocation of butt joint in the past is changed. The strength is 2.5 times higher than that in the past.

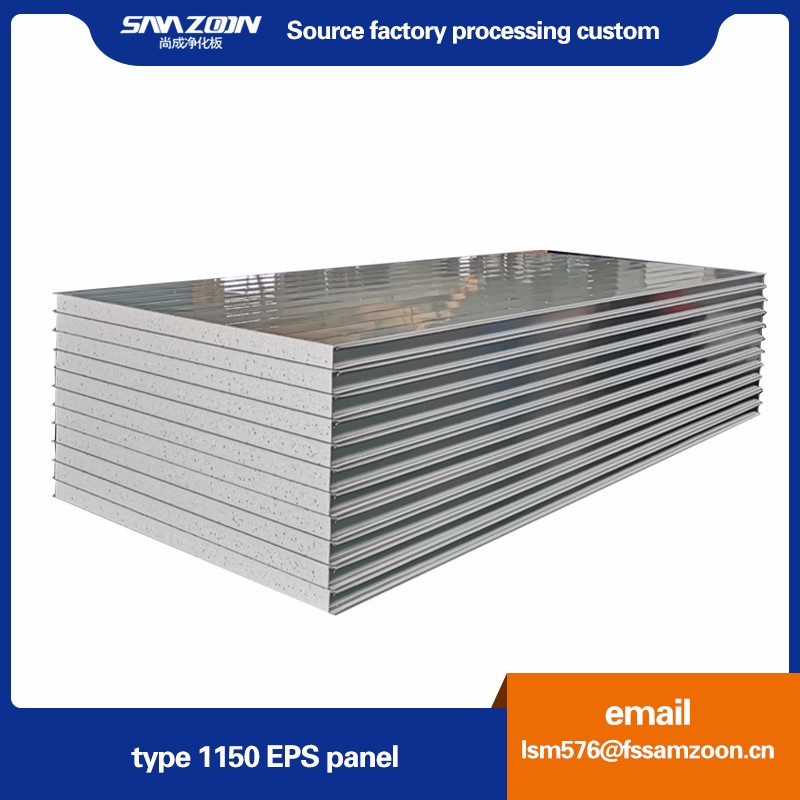

Product parameters:

Effective width: 960mm / 1050mm

Product thickness: 50 mm / 75 mm / 100 mm / 125 mm

Product length: according to the user's needs and engineering requirements and size production (generally ≤ 6000mm)

Product color: gray, ivory, sea blue, dream blue, can be customized according to customer demand

Core material: EPS board is made of expandable polystyrene beads containing volatile liquid foaming agent. It is a white object, flame retardant and fireproof grade B1, which is heated in the mold after pre heating.

Product performance:

Rust proof, acid alkali resistance, flame retardant, sound insulation, heat preservation, constant temperature and humidity, self-cleaning performance

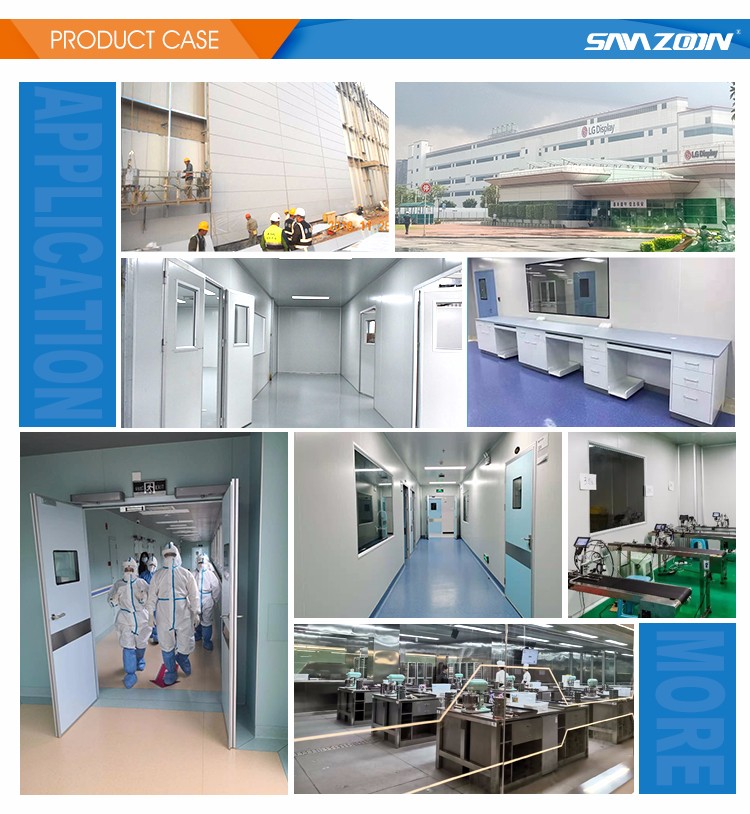

Product application:

Export EPS/ foam composite panels are widely used in roofing parts of large-span composite steel structures and grid structures, such as gymnasium, large workshop, conference center, auditorium, electric power train, building, agricultural Electronics (industrial workshop), medicine (purification room), chemical industry (fire prevention workshop) and other fields.