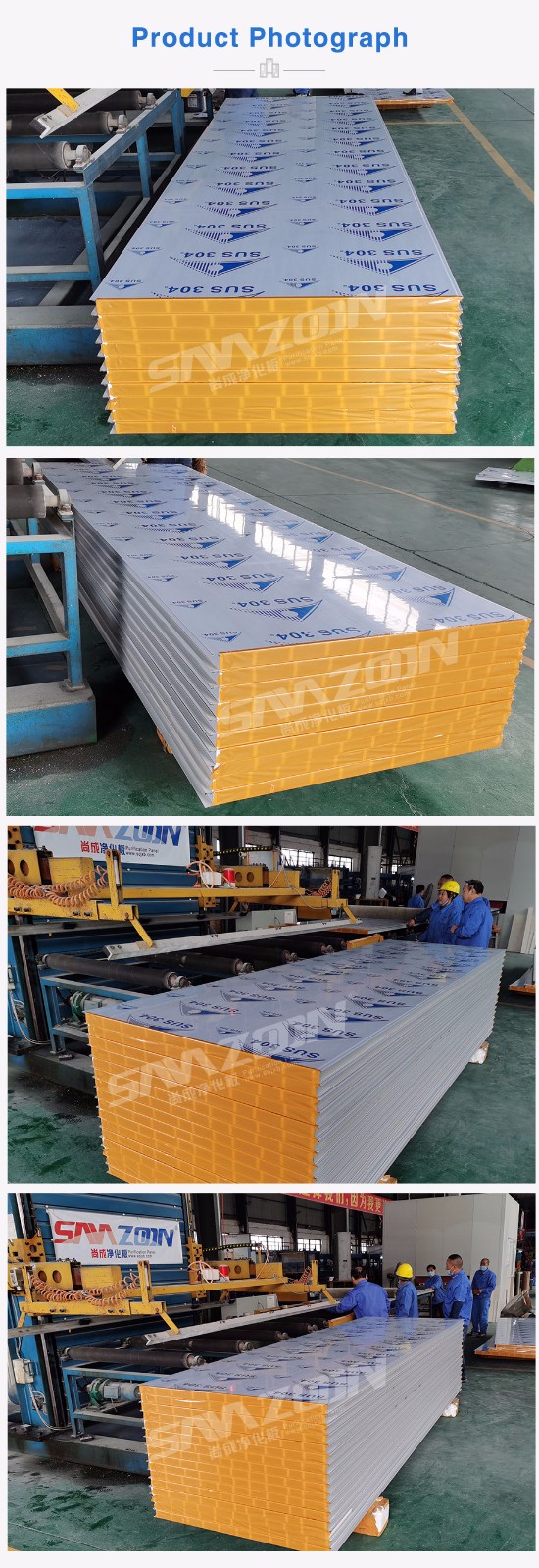

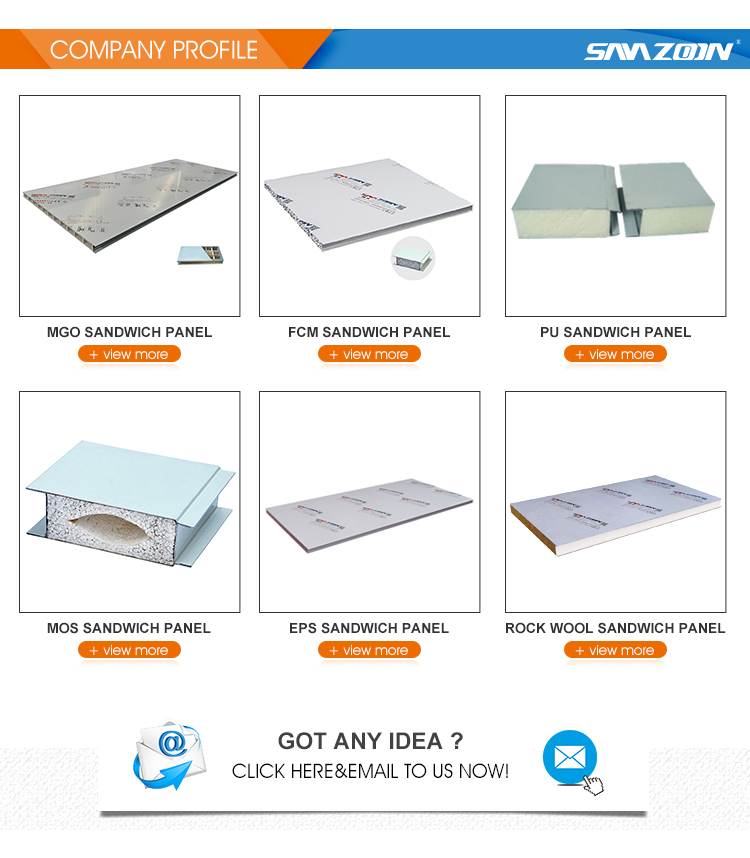

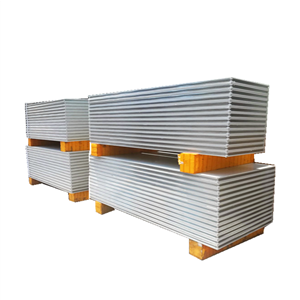

Modular Wall Panels Cleam Room Panel Manufacturer

- Samzoon

- Foshan, Guangdong, China

- 7-15days

- 5000-10000㎡/day

Product Description:

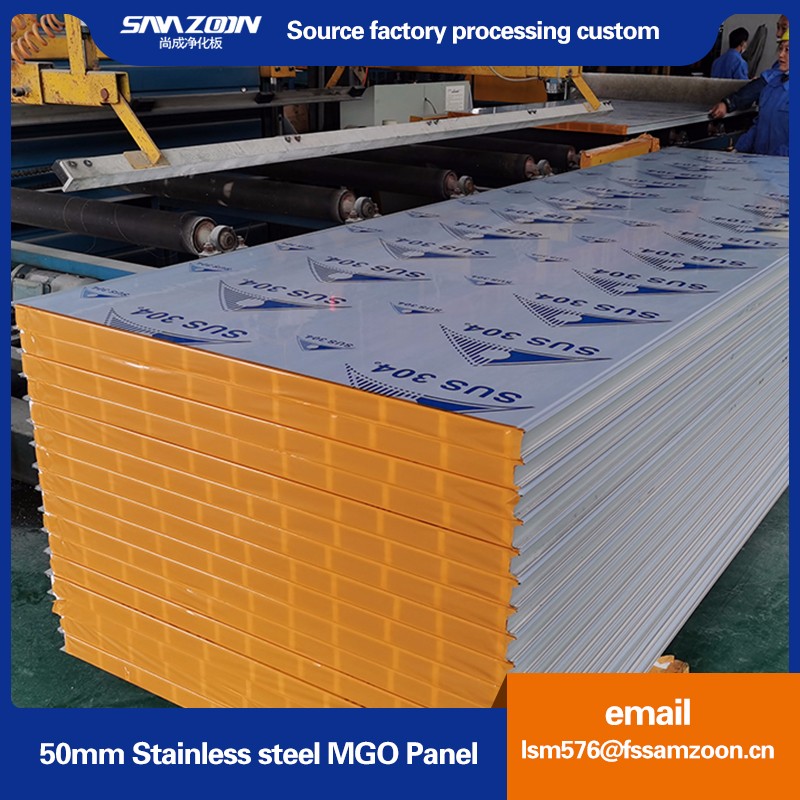

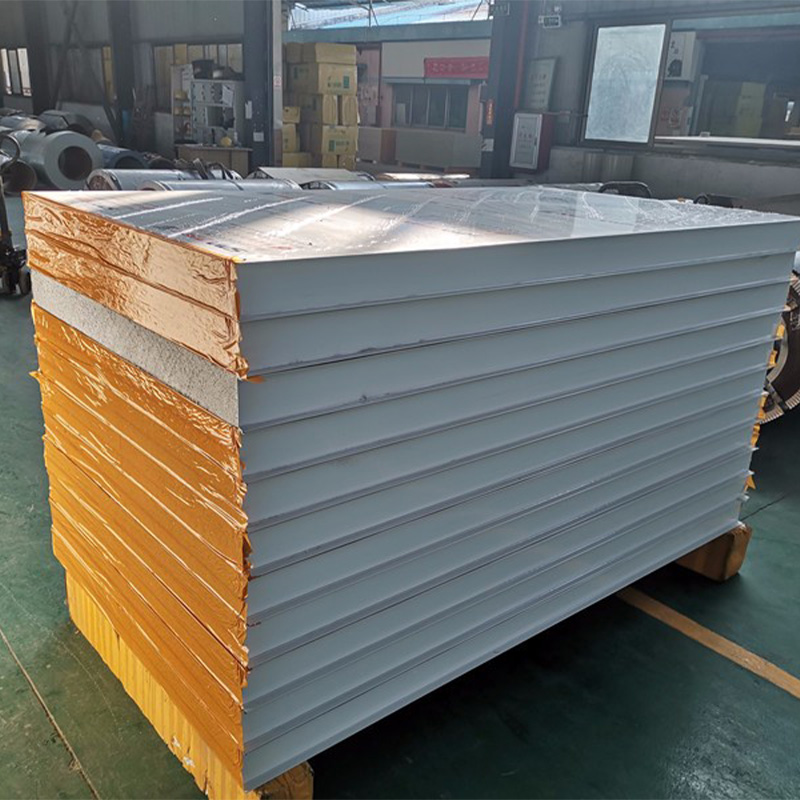

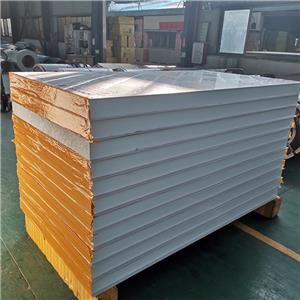

SAMZOON 50 mm / 1150 type stainless steel hollow glass magnesium composite plate has made innovation in structure. Firstly, the space spacing has been changed from 150 mm to 95 mm. Secondly, the male and female tenon connection method has been adopted for the head and tail connection of the core material. After more than 4 years of use test, the phenomenon of wrinkle and uneven waves on the surface of the return brine plate has been solved, and the problem of insufficient ceiling strength has been solved. Therefore, the anti rust, anti scrubbing, acid and alkali resistance, fire prevention, sound insulation, heat preservation, antibacterial, high strength, convenient installation, no halogen return, corrosion resistance, burst resistance, high temperature resistance, aging resistance and other properties are particularly good, and the materials are environmentally friendly, non-toxic and pollution-free.

Using stainless steel composite plate instead of the original pure stainless steel plate can reduce the cost of the equipment, but the use of the equipment is not affected. Stainless steel composite plate can be used in desulfurization tower, ammonia distillation tower and debenzylation tower with low cost and corrosion resistance; taking debenzylation tower as an example, the cost can be reduced by more than 30% by using stainless steel composite plate instead of pure stainless steel plate. 2. The stainless steel clad plate retains the corrosion resistance, wear resistance, magnetic resistance and beautiful appearance of pure stainless steel, and also has the good weldability, formability, tensile and thermal conductivity of carbon steel. It can be widely used in coking equipment to improve the corrosion resistance of coking equipment and prolong the service life of equipment. 3. Stainless steel clad plate has good thermal conductivity and anti-corrosion function, which can be widely used in coking equipment. If used in ammonia distillation tower, it can improve the service life of ammonia distillation tower and reduce the operation cost; on the other hand, because of its anti-corrosion performance, it can also be used in ammonia distillation equipment. In a word, stainless steel clad plate has great potential in the manufacturing, upgrading and transformation of coking equipment in China. It is the only choice to improve the service life of equipment, improve the production efficiency of equipment and reduce the operation cost.

Product parameters:

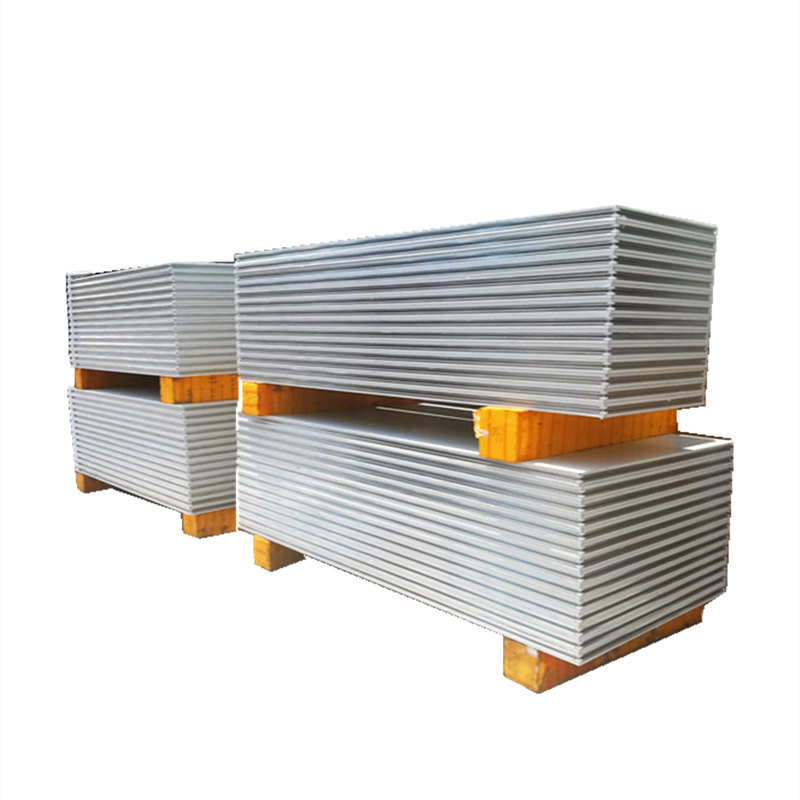

Effective width: 1150 mm

Product thickness: 50 mm / 75 mm / 100 mm

Product length: according to the user's needs and engineering requirements and size production (generally ≤ 6000mm)

Product color: gray, ivory, sea blue, dream blue, can be customized according to customer demand

Panel material: 304 stainless steel

Product core material: non halogen magnesium oxide, magnesium sulfate and brine ternary as the main raw materials, with alkaline glass fiber cloth as reinforcement material

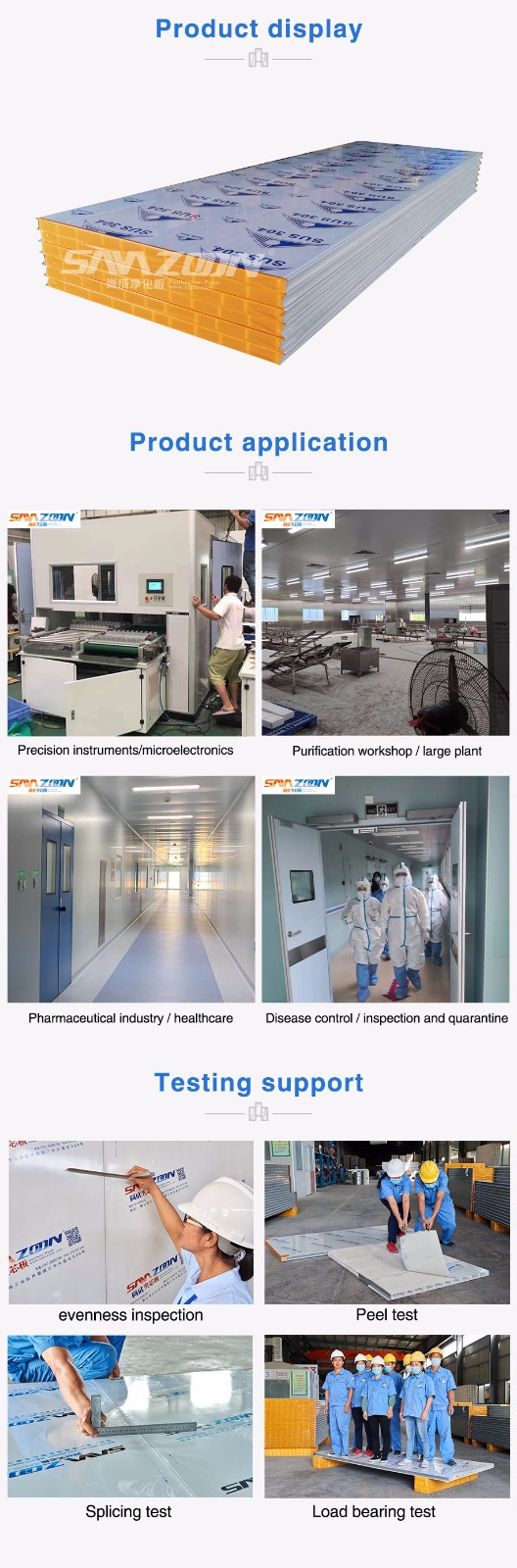

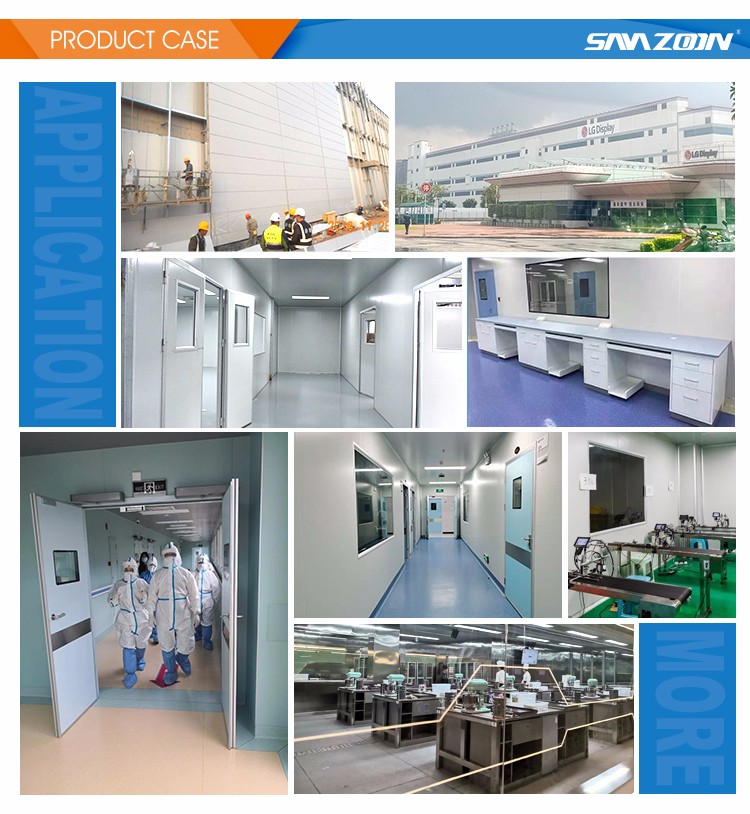

Product application:

Color steel purified glass magnesium mechanism composite board is suitable for laboratory, pharmaceutical industry, food processing, medical and health, disease control, inspection and quarantine, optical technology, laser technology, precision instruments, microelectronics and other industries.